While most cabin refurbishments focus on plush seats and mood lighting, one Florida company believes the next big upgrade lies in something passengers barely notice: the window shade.

The ATG Window Shade Family

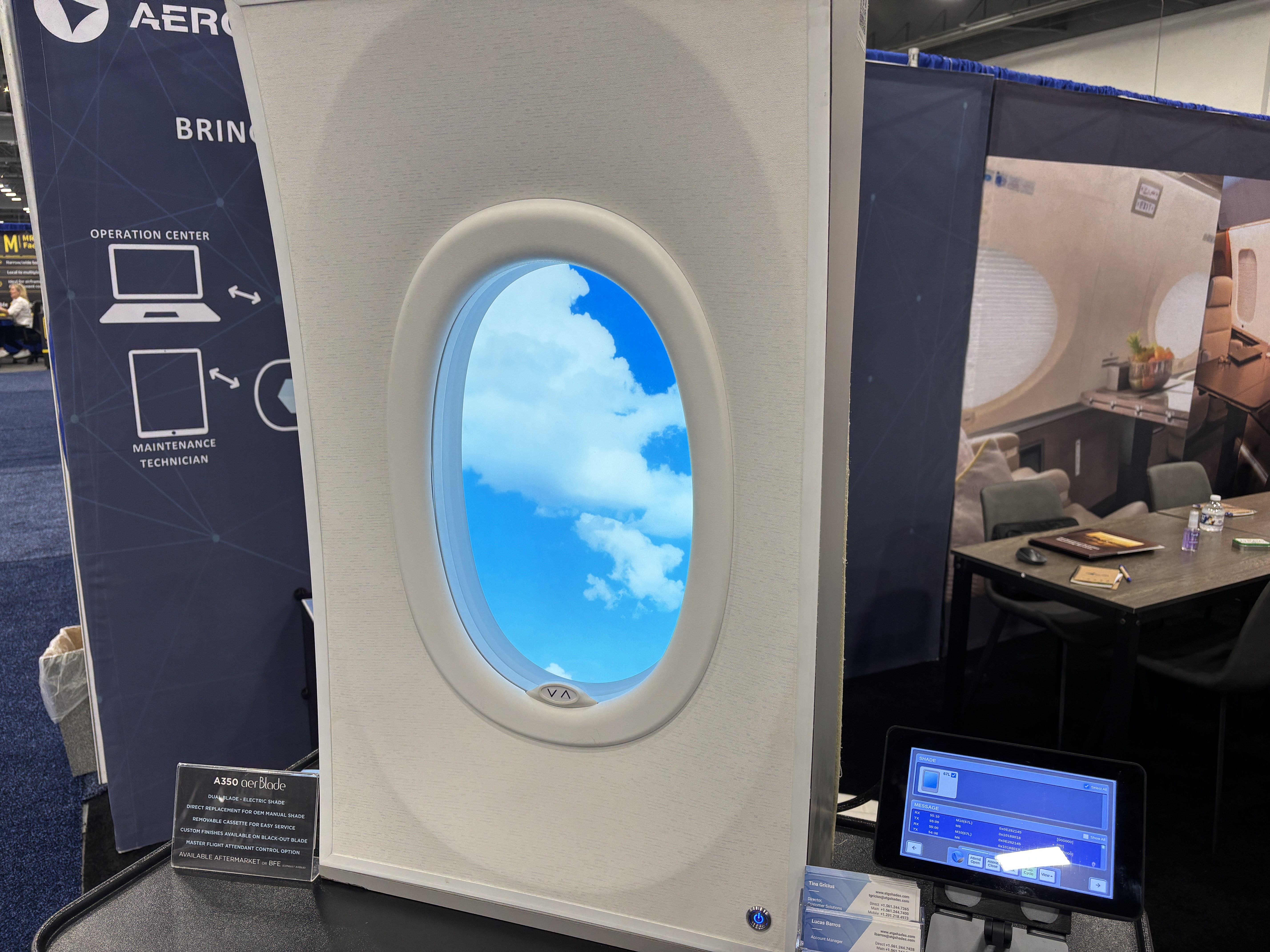

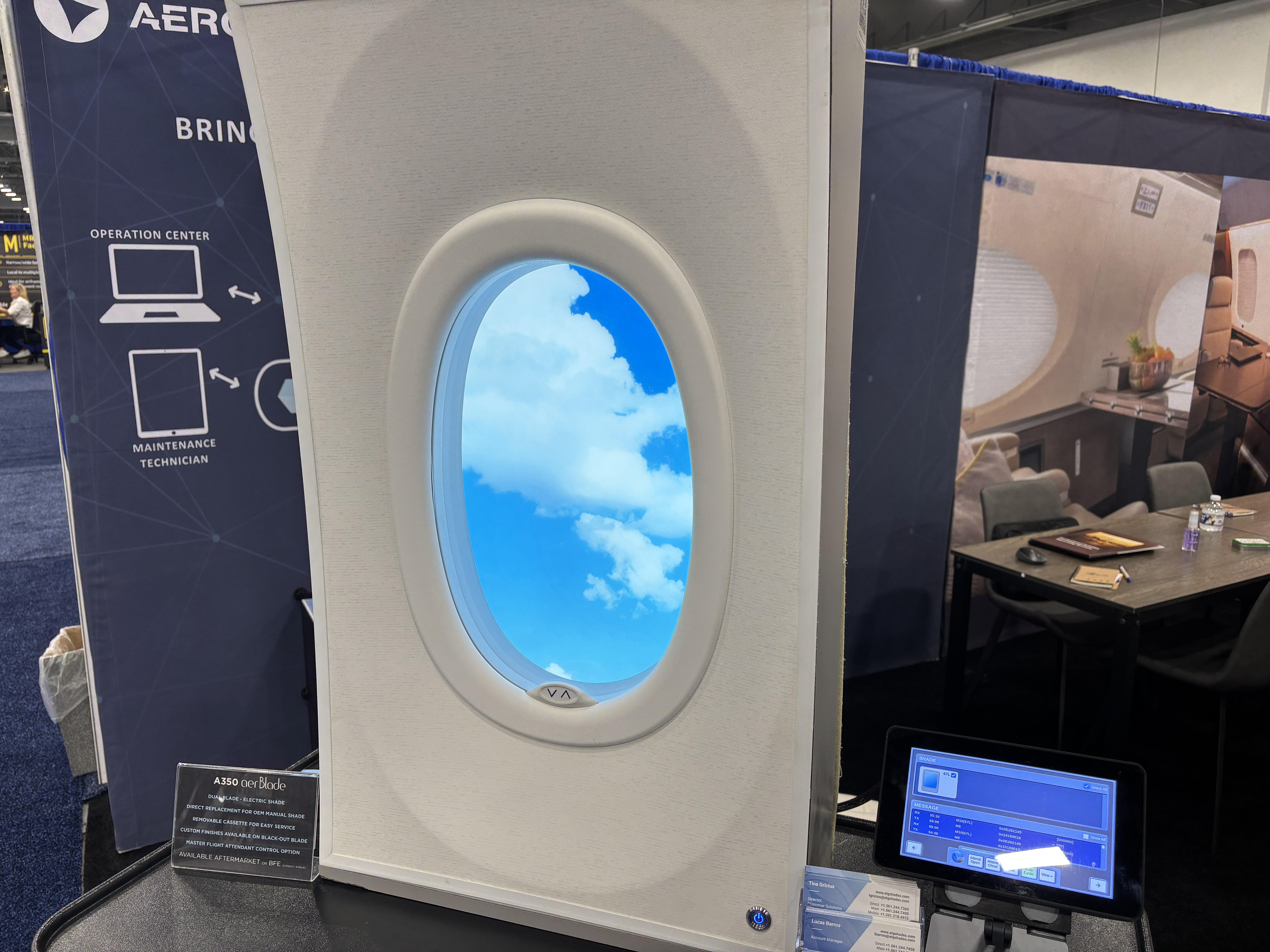

Aerospace Technologies Group (ATG) has seen success in the implementation of its aerBlade window shade system, which has already been introduced into service onboard certain commercial aircraft. The aerBlade — along with its sister product, aerLuxe — is part of the ATG window shade family, which was showcased at the 2025 NBAA-BACE event in Las Vegas.

Both products offer the latest technologies and updated electronics. The aerLuxe™ shade provides a single “picture” window blind comprised of both light filtering (translucent) and cabin darkening (opaque) modes. With the press of a single button, multiple windows disappear, replaced by a beautiful fabric wall covering that blends seamlessly with the surrounding interior.

However, aerLuxe™ most innovative benefits lie within, silently working to create the quietest and smoothest operating window shade in its class. The foundation of aerLuxe™ is based on ATG’s proven Modular Series of window shades, which has been elevated to a new level of performance through ATG’s Next Gen advanced electronic control system.

The company plans to introduce models of aerLuxe ™ for the range of commercial aircraft commissioned for VIP applications and will replace its MS2 and MS3 products.

The aerBlade can already be found throughout Emirates' new A350-900 fleet, including electrical shades with a single blackout blade in economy class. The latest aerLuxe products are now offered on VIP BBJ and ACJ completions.

Once installed, the shade connects directly to the aircraft's electrical system, allowing these shades to be controlled by the flight crew. ATG offers options for graphics on the aerBlade units, unlimited creativity for airlines. The aerLuxe unit remains a pleated dual fabric product.

Easy Installation and Maintenance

AeroXplorer had the opportunity to speak with Tina Mulligan, Director of Customer Solutions, and Lucas Barros, Account Manager at ATG. They shared how the aerBlade's simplistic design promotes easy installation and replacement, regardless of aircraft type.

When it is time for replacement, the aerBlade exhibits a modular design, able to be removed and replaced without the need for special tooling. The aerBlade unit can be exchanged within 3 minutes.

Mulligan also commented on the durability of the aerBlade's design. The device has undergone extensive certification testing, including fire-burn, electrical, and vibrational tests. Although the device will require individual certifications for each aircraft type it will be installed onto, this rigorous testing will ensure that the product is universally compliant, easing the process of achieving new certifications.

Although still a relatively new product, Barros indicates that the aerBlade is nothing short of a win for the airline. Beyond passenger comfort, the introduction of the system offers an additional source of revenue for airlines. ATG provides the option for customers to customize its shades with printed designs, presenting airlines with additional advertising space to be sold off.

Installation Challenges on Business Jets

According to Barros, ATG does occasionally face challenges when installing its shades, specifically with business jets. He shared that whilst most commercial aircraft utilize an open panel where windows can be removed with minimal effort, certain business jets are fitted with windows that are bolted into the fuselage. Thus, removal of the manufacturer-provided window shades requires the removal of the aircraft's entire side panel. However, he also noted that ATG has already communicated this difficulty to aircraft manufacturers and hopes that they will take this into account when designing future aircraft models, barring FAA certification.

Nevertheless, ATG brings innovation to the business aviation landscape by addressing an underserved issue on a global scale. As aircraft interiors become more personalized, products like ATG's aerBlade prove how big of an impact seemingly small changes can have on the passenger experience.

The Top 5 Longest Flights in the World » Why Fast Price Estimation Has Become Critical for Brokers and Clients » End of an Era: JetBlue's Farewell to the Embraer E190 »

Comments (6)

San Po Ho

If the window shades are motorized, then the flight attendants can have a master control to raise and lower them at their wish. This is the real motivation for automating the window shades.

San Po Ho

If the window shades are motorized, then the flight attendants can have a master control to raise and lower them at their wish. This is the real motivation for automating the window shades.

Dan Atatakai

I enjoy writings about aviation, both company and private.

Dan Atatakai

I enjoy writings about aviation, both company and private.

David

This is ridiculous. Manual window shades are smooth and simple. Just raise or lower your arm and extend a finger!

David

This is ridiculous. Manual window shades are smooth and simple. Just raise or lower your arm and extend a finger!

John Pork

Do you still crank down your car windows? This is the future; Humanity must advance and not stay stuck in these outdated pre-renaissance ways of thinking.

John Pork

Do you still crank down your car windows? This is the future; Humanity must advance and not stay stuck in these outdated pre-renaissance ways of thinking.

Larry

And some airline (AA & SWA I'm looking at you) will find a way to place ads on them

Larry

And some airline (AA & SWA I'm looking at you) will find a way to place ads on them

Skip Frary

I always select a window seat and enjoy looking out of it.

I do see that on early morning or sunset flights, the glare affects other passengers ability to view their IFE screens. Before we go overboard and start selling advertisements on the window shades….I remember when the only paint on the Green Monster in Fenway Park was GREEN…. how about a clear tinted sunshade to allow passengers to enjoy the view and reduce the glare for those watching IFE or using their own devices ?

Skip Frary

I always select a window seat and enjoy looking out of it.

I do see that on early morning or sunset flights, the glare affects other passengers ability to view their IFE screens. Before we go overboard and start selling advertisements on the window shades….I remember when the only paint on the Green Monster in Fenway Park was GREEN…. how about a clear tinted sunshade to allow passengers to enjoy the view and reduce the glare for those watching IFE or using their own devices ?

Add Your Comment

SHARE

TAGS

STORIES ATG Aerospace Technologies Group Window Shade Startups aerBlade aerLuxeRECENTLY PUBLISHED

Delta Sets Firm October 2026 Launch for Historic Atlanta–Riyadh A350 Service

Delta Air Lines has officially locked in the launch date for its highly anticipated nonstop service to Saudi Arabia, marking a milestone as the first U.S. carrier to offer direct flights to the Kingdom's capital.

ROUTES

READ MORE »

Delta Sets Firm October 2026 Launch for Historic Atlanta–Riyadh A350 Service

Delta Air Lines has officially locked in the launch date for its highly anticipated nonstop service to Saudi Arabia, marking a milestone as the first U.S. carrier to offer direct flights to the Kingdom's capital.

ROUTES

READ MORE »

Game Day: The Unseen Operation Behind College Sports Travel

At one of the largest Division I programs in the country, six-figure sports charters quietly keep game day moving. We went airside at the University of Illinois-Willard Airport to see who plans them, how aircraft and crews are positioned, and why a single schedule change can ripple through an entire airline.

STORIES

READ MORE »

Game Day: The Unseen Operation Behind College Sports Travel

At one of the largest Division I programs in the country, six-figure sports charters quietly keep game day moving. We went airside at the University of Illinois-Willard Airport to see who plans them, how aircraft and crews are positioned, and why a single schedule change can ripple through an entire airline.

STORIES

READ MORE »

Coloring the Clouds: How ANA Turned Airplanes into Art

ANA's long-running tradition of special liveries has transformed its fleet into a flying gallery of Japanese culture, featuring iconic partnerships with franchises like Pokémon, Star Wars, and Demon Slayer. We explore these liveries and the stories behind them.

INFORMATIONAL

READ MORE »

Coloring the Clouds: How ANA Turned Airplanes into Art

ANA's long-running tradition of special liveries has transformed its fleet into a flying gallery of Japanese culture, featuring iconic partnerships with franchises like Pokémon, Star Wars, and Demon Slayer. We explore these liveries and the stories behind them.

INFORMATIONAL

READ MORE »